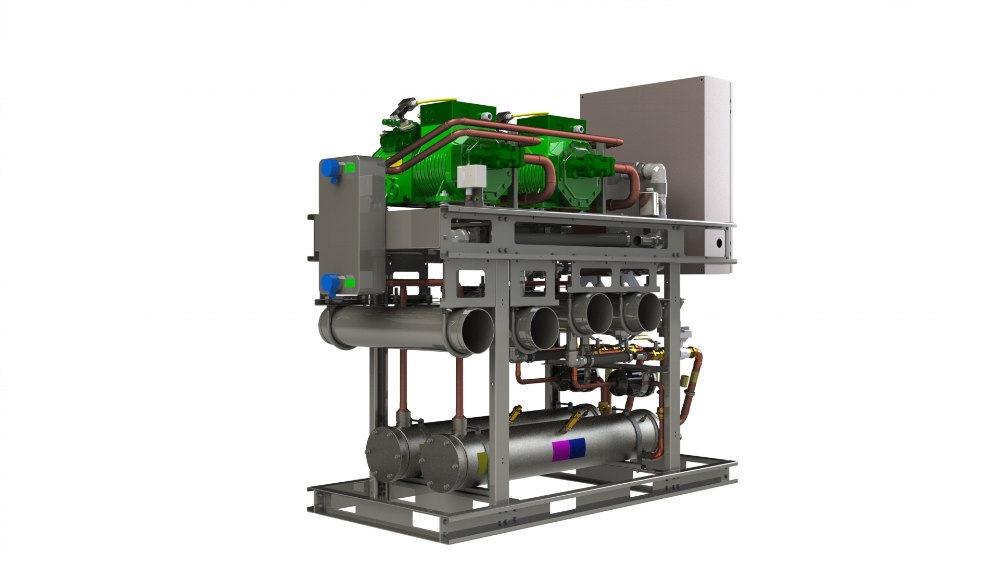

Water Cooled

ModulAIR is a water cooled chiller that brings robust serviceability and ASHRAE 90.1-2010 efficiency into a single compact package. Standard features such as cleanable shell & tube condensers and replaceable filter driers means that customers no longer need to sacrifice reliability when choosing a modular design. Each module can be used as a stand-alone chiller or combined with the optional header system for installations up to 550 tons. The unique control algorithms are duplicated in each chiller module eliminating the need for any master controller which improves redundancy for critical applications.

Built for Service

Other commercial or industrial units are built as throwaway units or are so hard to service that it is easier to just replace the unit. All AIR units are designed and built with the service technician in mind. We are able to do this by take the learning and difficulties that we see in the field and pass that information to our engineering team to enhance our units.

1. Cleanable shell & tube condensers

2. Serviceable compressors for industrial reliability

3. Replaceable filter drier with isolation valves

4. Condenser isolation valves for in-operation service

5. Service clearance required at front of unit only

Heat Recovery

Key Features

• Capacities from 8 to 55 tons

• Modular design expandable up to 550 tons

• Autonomous controls in each module

• Water-to-water Heat Recovery up to 195 F

• Single and dual independent refrigerant circuits

• Shell & tube condenser

• Brazed plate evaporator

• Stainless steel frame structure

• Compressor oil monitoring

• Infinite unloaders for capacity control from 10 to 100%

• High and low pressure avoidance sequence

• Easy to use operator interface

The ModulAIR Heat Recovery Series delivers significant energy savings by recovering energy for applications where heating and cooling are required. Condenser heat that would otherwise be wasted can now be used for space heating, domestic hot water, or any other heating process. Because of its advanced controls, the ModulAIR can perform as a conventional chiller when cooling is required and switch into heat recovery mode when heating and cooling are both required. For ultimate flexibility, the unit is available with a dual condenser option. This allows users to recover heat when needed or reject the heat through the second condenser when there is no heat load.

Air Cooled

ModulAIR is a air cooled chiller that brings robust serviceability and ASHRAE 90.1-2010 efficiency into a single compact package. Standard features such as a stainless steel frame structure and replaceable filter driers means that customers no longer need to sacrifice reliability when choosing a modular design. Each module can be used as a stand-alone chiller or combined with the optional header system for installations up to 400 tons. The unique control algorithms are duplicated in each chiller module eliminating the need for any master controller which improves redundancy for critical applications.

Key Features

• Capacities from 10 to 40 tons

• Modular design expandable up to 400 tons

• Autonomous controls in each module

• Compressor staging based on energy efficiency

• Single and dual independent refrigerant circuits

• Copper tube, aluminum fin condenser

• Brazed plate evaporator

• Stainless steel frame structure

• Compressor oil monitoring

• Infinite unloaders for capacity control from 10 to 100%

• High and low pressure avoidance sequence

• Easy to use operator interface

Built for Service

Other commercial or industrial units are built as throwaway units or are so hard to service that it is easier to just replace the unit. All AIR units are designed and built with the service technician in mind. We are able to do this by take the learning and difficulties that we see in the field and pass that information to our engineering team to enhance our units.

1. Cleanable v-coil air cooled condensers

2. Serviceable compressors for industrial reliability

3. Replaceable filter drier with isolation valves

4. Evaporator isolation valves for in-operation service

5. Built in electrical cabinet

6. Compressor weatherproof enclosure